Apex Microtechnology

Apex Microtechnology

Apex Microtechnology 是 HEICO Corporation 的子公司,在精密功率類比元件的設計和開發方面處於行業領先地位,這些元件用於控制高可靠性應用中的電流、電壓和速度。 Apex 支援廣泛的市場,包括工業、半導體、醫療、航太以及航空航太和國防。

Apex 的產品組合包括高效能功率運算放大器(線性放大器)、脈衝寬度調變(PWM 和 D 類開關放大器)、精密積體電路 (IC)、整合式電源模組和精密電壓基準。這些解決方案提供多種外形尺寸,包括單晶片積體電路、板級開放式框架模組和傳統的混合設計。 Apex 產品能夠提供高達 40 A 的連續輸出電流,工作電壓範圍為 5 V 至 2500 V。

為了支援不同的應用環境,Apex 提供多種篩選等級的產品:商用/工業級、軍用等級(M 級)、完全符合「M/883」標準以及耐輻射 (R) 裝置。這使得客戶能夠選擇滿足其特定性能、環境和可靠性要求的解決方案——無論是用於堅固耐用的工業系統還是關鍵任務型航空航天平台。

Apex 總部位於亞利桑那州圖森,採用垂直整合營運模式,結合內部工程和製造專業知識,提供更高的靈活性、品質控制和對客戶需求的回應能力。這種模式支援快速創新,同時確保產品的長期一致性和可用性—這對我們高可靠性市場的客戶至關重要。

我們對卓越的承諾以一項品質政策為指導,該政策強調四項關鍵指令:首先滿足客戶需求、提供有競爭力的解決方案、遵守所有適用要求以及持續測量和改進。 Apex 已通過 ISO 9001 和 MIL-PRF-38534 混合微電路標準認證,體現了我們對最高品質和合規性的執著追求。

在 Apex Microtechnology,模擬設計和混合製程控制的專業知識在我們整體的產品品質和性能中得到了充分體現。 Apex 不僅設計高功率類比元件,更致力於打造客戶信賴的產品。 Apex 產品在全球各地備受信賴,廣泛應用於對精確度、可靠性和長壽命至關重要的應用領域。

Apex Microtechnology, a subsidiary of HEICO Corporation, is an industry leader in the design and development of precision power analog components used to control current, voltage, and speed in demanding high-reliability applications. Apex supports a broad range of markets including industrial, semi-cap, medical, space, and aerospace & defense.

Apex’s product portfolio includes high-performance power operational amplifiers (linear amplifiers), pulse width modulation (PWM and Class D switching amplifiers), precision ICs, integrated power modules, and precision voltage references. These solutions are offered in multiple form factors, including monolithic ICs, board-level open-frame modules, and traditional hybrid designs. Apex products are capable of delivering continuous output currents up to 40 A and operating at voltage levels from 5 V to 2500 V.

To support diverse application environments, Apex offers its products in multiple screening levels: commercial/industrial, military-grade (M-grade), full “M/883” complaint, and radiation-tolerant (R) devices. This allows customers to choose solutions that meet their specific performance, environmental, and reliability requirements—whether for rugged industrial systems or mission-critical aerospace and space platforms.

Operating in a vertically integrated headquarters in Tucson, Arizona, Apex combines in-house engineering and manufacturing expertise to offer greater flexibility, quality control, and responsiveness to customer needs. This model supports rapid innovation while ensuring long-term product consistency and availability—critical factors for our customers in high-reliability markets.

Our commitment to excellence is guided by a quality policy that emphasizes four key directives: Satisfy the Customer First, Provide Competitive Solutions, Comply with All Applicable Requirements, and Measure and Improve Continually. Apex is certified to both ISO 9001 and MIL-PRF-38534 Hybrid Microcircuit standards, reflecting our dedication to the highest levels of quality and compliance.

At Apex Microtechnology, expertise in analog design and hybrid process control shines through in our overall product quality and performance. Apex doesn't just design high power analog components—Apex engineers customer confidence. Apex products are trusted around the world in applications where precision, reliability, and longevity are essential.

產品展示

SA111

Created with Silicon Carbide (SiC) technology and leading-edge package design, the SA111 is expanding the boundaries of thermal efficiency and power density in analog modules. In a surface mount package and with a body of just 20mm x 20mm, the SA111 can provide continuous output currents of 32A, manage supply voltages of up to 650V, and achieve switching frequencies of up to 1MHz. This thermally efficient package utilizes top-side heat sinking, allowing the user to maximize board layout. The SA111’s Silicon Carbide MOSFETs enable the device to withstand higher thermal stress, managing junction temperatures of up to 175°C. The SA111 SiC power module offers a fully integrated solution allowing for increased device control and protection, featuring an integrated gate driver, under-voltage lockout, and active Miller clamping.

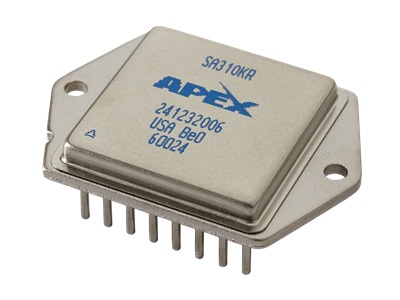

SA310

The SA310 is a fully integrated three-phase driver designed primarily to drive Brushless DC (BLDC) and Permanent Magnet Synchronous (PMSM) motors or DC/AC converters. The module uses Silicon Carbide MOSFET technology to improve efficiency over other devices in its class. Three independent half-bridges provide up to 80A peak output current under direct microcontroller or DSC control. SA310 is built on a thermally conductive, but electrically isolated substrate to provide the most versatility and ease in heatsinking. The amplifier protection features include Under-voltage lockout (UVLO) function and active Miller clamping to reduce switching noise and improve reliability. Also included in the module are Silicon Carbide Schottky Barrier free-wheeling diodes to protect the body diode of each MOSFET. No external output protection diodes are required. The SA310's integrated gate drivers provide transformer isolation between the inputs and high-voltage outputs.